THE KANBAN PRINCIPLE: OPTIMUM PRODUCTION PROCESS CONTROL THANKS TO THE KANBAN SYSTEM

Kanban principle – Good to know

The Kanban principle was originally developed by Taiichi Ohno at Toyota in Japan in 1947. It is a system based on the pull principle for controlling material flow and production. The goal is to ensure a seamless material supply for production. Traditional Kanban systems use two bins in a cycle and mostly Kanban cards as information carriers to control the production process. All details such as item number and description, filling quantity of the bin and supplier are put on this information carrier.

Kanban process at Würth – Delivery security for your small parts

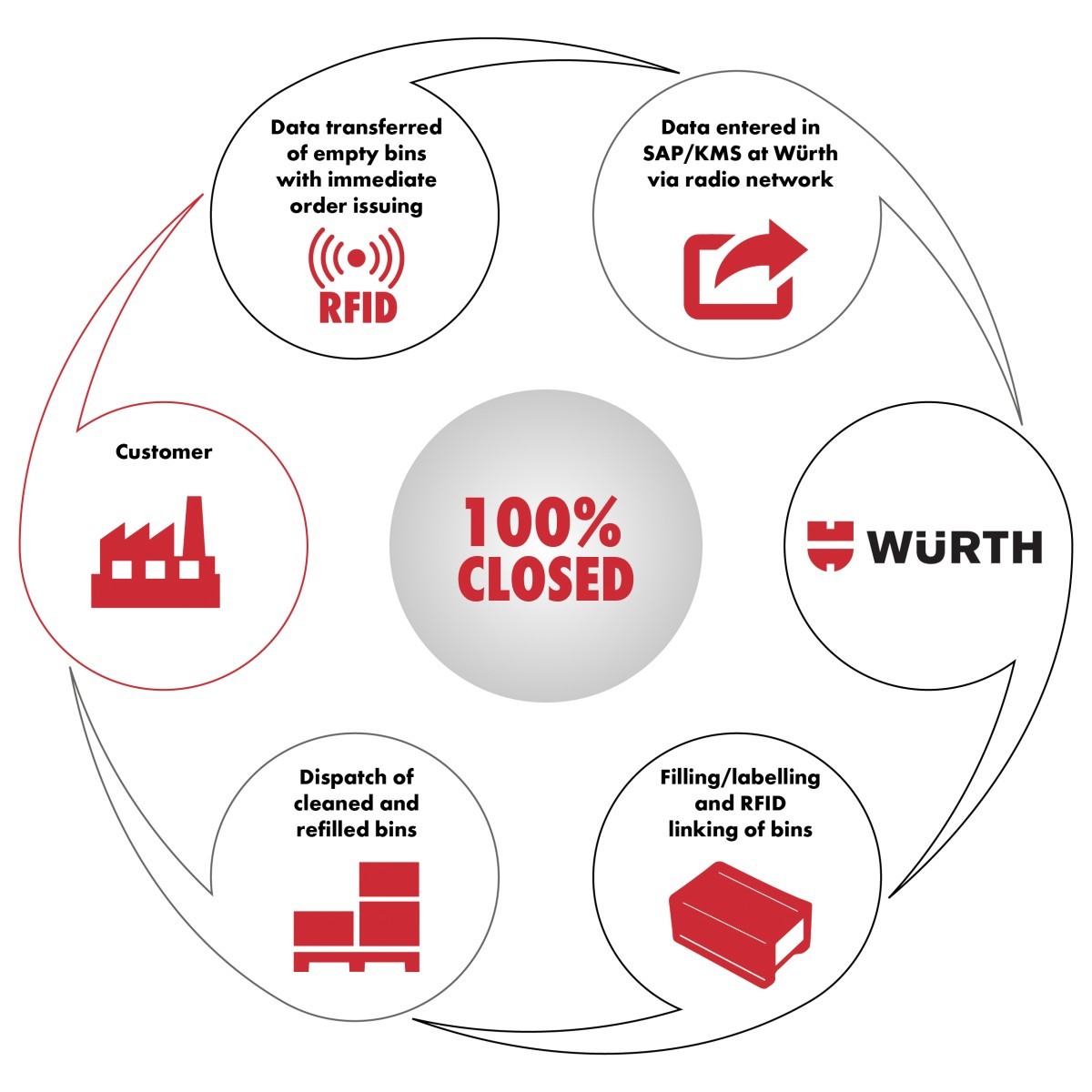

The material flow is managed in Kanban systems by Würth Industry via two bins, our Würth small load carrier W-KLT®2.0. The information carriers used are a Kanban label in combination with various technologies for the automatic control of your production process. In the past, a hand scanner was used to trigger the demand, today more than half of our customers use standard RFID-based system solutions for automated reordering.

In the Kanban system of Würth Industry you can manage your direct materials such as fasteners, fastening technology, DIN / standard parts as well as special and drawing parts but also your indirect needs in the field of MRO, operational and auxiliary materials.